How to Select a Replacement Seal Kit for Your Piston Pump

Replacing damaged seals in a piston pump is essential for ensuring optimal performance because seals help maintain hydraulic fluid pressure. A pinched or torn seal will lead to a loss of pressure, which can cause extensive damage to a pump.

The challenge of seal replacements is that each seal is unique to the pump, so there are no universal kits available—each piston pump seal kit, which includes O-rings, washers, and gaskets, matches OEM specifications to ensure a proper fit.

To ensure you select the right kit for your pump, you’ll need to follow these steps:

1. Identify the Pump Model & Specifications

The most important step in matching any replacement seal kit is identifying the pump model.

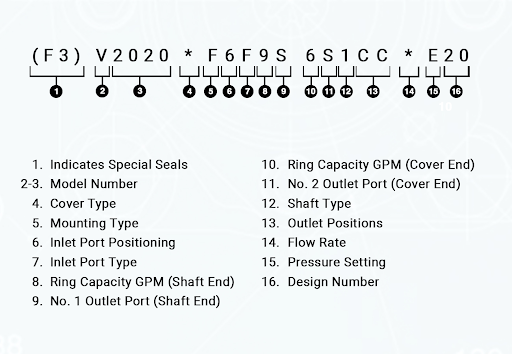

Like a fingerprint, the model number will have information on the pump’s specifications and specific components, including the number, sizes, dimensions, and material types for the O-rings, gaskets, seals, etc.

Finding the model number should be relatively easy. However, there are times when an aged pump has a missing or worn-out identification number. For more information on identifying your piston pump in these situations, please visit How to Identify Your Piston Pump Model.

2. Know What Material You Need

Using the right seal material is an absolute must. Different materials have different properties and are designed for specific operating parameters. Some materials can withstand extreme temperatures, while others are more suited to particular pressure ratings or may be designed for different mating surfaces.

Choosing the wrong material will lead to the seal failing prematurely, as it will most likely be unable to handle the pressure and temperature of your system. Typical materials for seals and O-rings include Nitrile (Buna-N), Viton (FKM), and Ethylene Propylene Diene Monomer (EPDM).

Nitrile is an excellent general-purpose material. It has sufficient abrasion, compression, and water resistance but doesn’t hold up well under high temperatures. Viton has excellent chemical resistance properties, can handle high temperatures, and has a wider operating temperature range than Nitrile. Lastly, EPDM has fantastic abrasion, steam, and tear resistance, can withstand different weathering environments, and is ideally suited for specific hydraulic fluids.

Seal material must be compatible with your pump’s hydraulic fluid and system application. Again, the pump’s model number comes into play here. For example, on older Vickers/Eaton pumps, that model number might contain an “F3” designation if specific Viton O-rings are required.

3. Size the O-Ring & Seal

In some cases, the O-ring and seal dimensions are written on the O-ring and seals themselves. In other instances, you may have a spare kit with a label on the bag. However, if you must size the O-ring and seal, there is a right and wrong way.

The wrong way is to remove them from their housing and base the measurements on the O-rings and seals. The material within O-rings and seals react differently to different operating conditions. Some will expand, while others will retract.

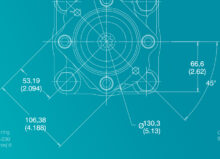

Measuring outside diameter

The right way is to measure the grooves where the O-ring and seal are placed. Measure the inside diameter (ID), outside diameter (OD), and the cross-section (CS).

Measuring inside diameter

Taking the measurements from the grooves ensures you’re not improperly fitting O-rings and seals, which can lead to excessive hydraulic oil leaks that can damage the piston and cylinder.

How to Replace Seals

A seal kit typically comes with instructions, which vary depending on the pump type. The most important step when replacing seals is to always make sure you’re replacing them in a clean, contaminant-free area. Wipe down the area before to ensure there is no dirt, debris, or residue.

Assuming you don’t have instructions, the following are the general guidelines for replacing seals. You’ll need a rubber mallet, torque, box and hex-head wrenches, a two-pin or hook-nose spanner, snap ring pliers or punch pliers, and a ratchet.

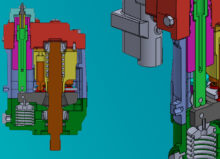

1. Disassemble Cylinder

There are four main types of piston pumps. These include axial, radial, lift, and force. Each can have a different type of cylinder. However, for the most part, these cylinders are either single-acting or double-acting, with the double-acting having two ports.

Always take your time when disassembling the cylinder, paying close attention to where each seal is placed and documenting all the parts of the pump. Write down how many rod or piston seals you removed and where you removed them.

2. Remain Vigilant for Signs of Damage

Always look for signs of damage on the seals and all hydraulic pump parts. Once you’ve removed the cylinder, inspect it for corrosion, scratches, dents, indentations, or pitting. You can also run your fingers along it to ensure its smoothness. If you notice any damage, the part will need to be replaced. If you don’t, move on to step three.

3. Replace the Seals

Always replace each seal one at a time, paying close attention to any abnormalities, defects, or damage. Clean the groove where the seal was removed with a lint-free cloth. If you notice excessive damage on the seal, inspect the groove to see what caused it. Small particles of dirt, mud, debris, or tiny metal shards can easily tear or pinch seals. Make sure to lubricate the replacement seal properly.

4. Reinstall & Test

After reinstalling the cylinder:

- Test it to ensure it’s working properly.

- Reconnect everything and run the pump.

- Watch for any leaks. If there are leaks, you may need to replace the seal again or have the pump professionally inspected.

Buy OEM-Equivalent Replacement Seal Kits

Panagon Systems is one of the largest manufacturers of aftermarket hydraulic piston pumps in the United States. In addition to manufacturing high-quality replacement pumps, we provide reliable, OEM-equivalent replacement seal kits and other parts for Vickers/Eaton/Danfoss and Rexroth piston pumps.

Please visit our website to learn more about our replacement parts, or complete this form to place your order or speak with one of our product specialists.