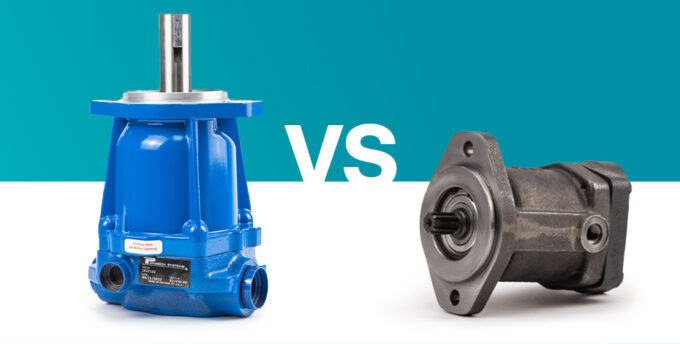

Fixed Versus Variable Displacement Hydraulic Pumps: Which One Do You Need?

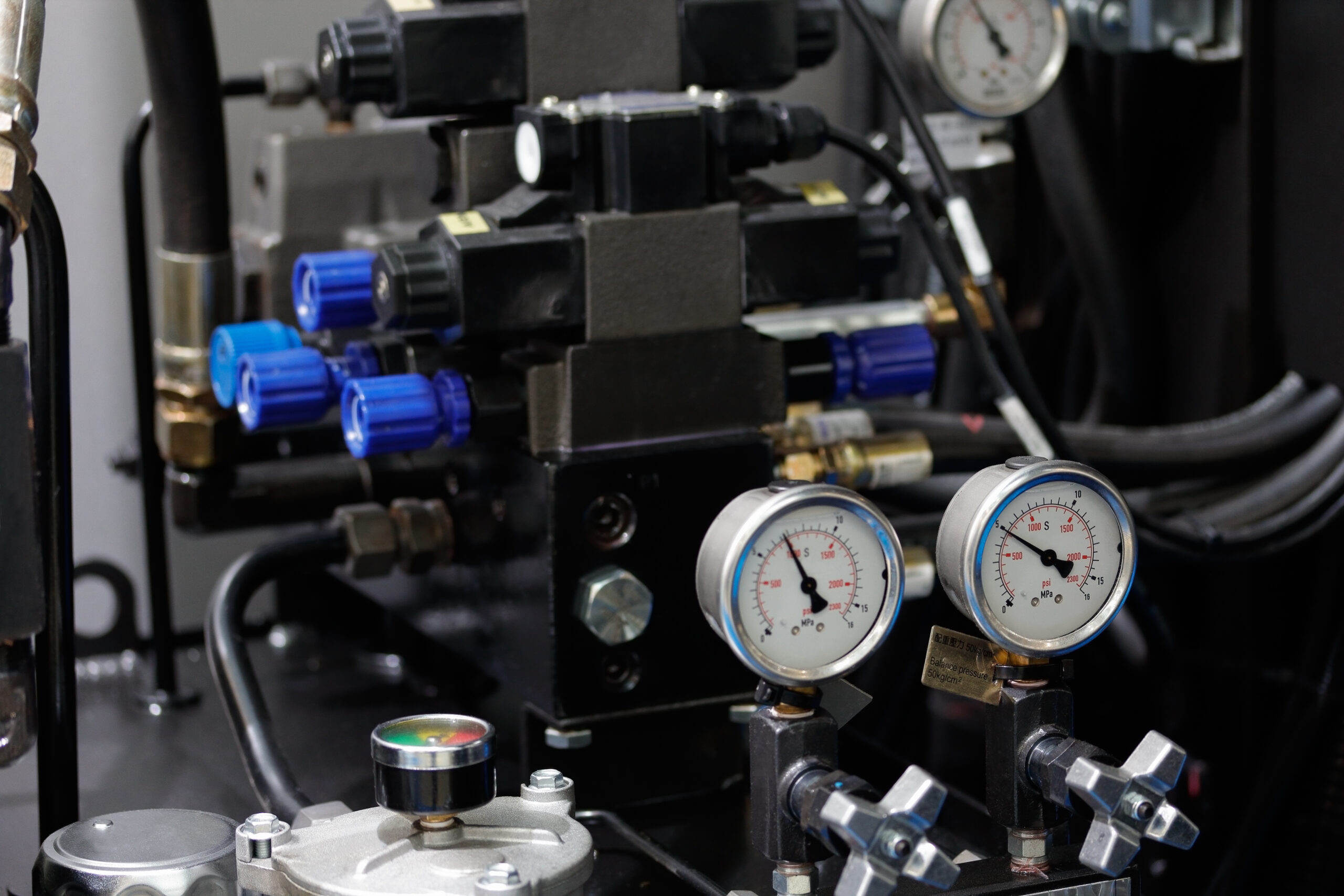

The hydraulic pump plays an essential role within a hydraulics system by converting electrical energy from the electric motor into fluid energy. The hydraulic pump is responsible for creating the hydraulic fluid pressure that activates the hydraulic system’s actuators (cylinders).

There are two primary types of hydraulic pumps to choose from: fixed displacement and variable displacement. Choosing the right kind of pump is essential to generating the correct amount of fluid pressure and volume while ensuring the pump and hydraulic system operate efficiently. It’s ultimately about optimizing the performance of your system while proactively controlling costs.

Keep reading to learn more about the differences between fixed and variable displacement hydraulic pumps and how to select the best type based on your application.

What Is a Fixed Displacement Pump?

A fixed displacement hydraulic pump is ideal when you need a predetermined and constant fluid volume for each pumping cycle. They are referred to as fixed displacement pumps because the volume of fluid pressure for every stroke is fixed.

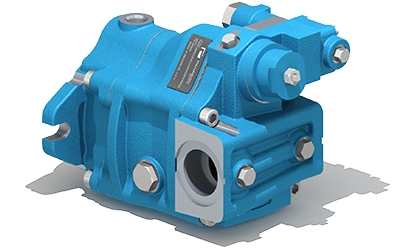

Internal gear and external gear pumps are both examples of fixed displacement pumps as they generate a constant flow rate. Gear pumps are inexpensive, don’t produce much heat, operate at high speeds, generate high flow rates, and are relatively quiet during operation. Vane and piston pumps can also be fixed.

Common Applications

Fixed displacement pumps are ideally suited for equipment and machinery that require high fluid pressures. These pumps can also handle a wide range of viscosities and are ideal for industrial manufacturing environments where dirt and debris are present.

Common applications for fixed displacement pumps include:

- Material Handling

- Machine Tools

- Conveyors

- Industrial Manufacturing Machines

- Marine Applications

- Agricultural Equipment

- Lubrication Systems

Considerations

Know your application’s flow rate requirements. If your hydraulic system or equipment requires a fixed rate of liquid flow and pressure, then a fixed displacement pump is the ideal match.

Another consideration is whether you require a consistent operational speed. In this instance, a fixed displacement pump may be the best solution.

What Is a Variable Displacement Pump?

The variable displacement hydraulic pump is called variable because the fluid volume per stroke can be altered or changed electronically, hydraulically, or manually during operation.

Because of its ability to adjust its flow rate for different applications, the variable displacement pump is more complex in its design. As such, it’s a more expensive pump, and its maintenance and upkeep costs are higher than a fixed displacement pump. However, the costs are offset by its energy efficiency and ability to operate different equipment.

Common Applications

You’ll often find variable displacement pumps in heavy-duty industrial, commercial, and construction equipment like cranes, excavators, and backhoes, or any application where fluid pressure must adjust for different loads.

General applications for these pumps include:

- Cranes

- Excavators

- Backhoes

- Industrial Automation Systems

- High-Performance Machine Tools

- Marine Propulsion Systems

- Mining Equipment

- Medical Devices

- Wind Turbines

- Injection Molding Machines

- Some Harvesters & Tractors

Considerations

Again, it all comes down to your system’s required flow rate. If your application requires that the speed or flow rate be controlled manually or electronically, then a variable displacement pump is required. And if your application requires that your flow rate adjusts in real-time based on different equipment or load capacity, then a variable pump is needed.

Select the Right Hydraulic Pump With Help From Panagon Systems

For over 25 years, Panagon Systems has developed an unsurpassed reputation as the largest manufacturer and aftermarket supplier of hydraulic piston pumps and rotary vane pumps in the United States. We can manufacture, refurbish, and test all Eaton/Vickers and Rexroth pumps up to 3000 PSI.

Please contact us today if you need help selecting the right hydraulic pump or aftermarket solution.