Fundamentals of Hydraulic Motors

If you are interested in getting the most out of your hydraulic motor, you need to understand the fundamentals of how these motors work. That way, you can quickly and efficiently find the best motor to meet your needs. So, what hydraulic motor is best for your company? Take a look at some important points below, and remember to reach out to professionals who can help you find the best hydraulic motor for your business.

Quick Facts on Hydraulic Motors

Before diving into the details regarding hydraulic motors, there are a few quick facts you need to know. Some of the most important facts you need to understand regarding hydraulic motors include:

- A hydraulic motor usually operates by taking advantage of changes in pressure and liquid velocity to generate force.

- Instead of using a linear cylinder, a hydraulic motor uses pressure to rotate itself.

- There are numerous types of hydraulic motors available. A few common examples include axial piston motors, radio piston motors, hydraulic gear motors, and hydraulic vane motors.

- A hydraulic motor is a durable option that can last a long time as long as it is taken care of appropriately.

- Because hydraulic motors come in all shapes and sizes, you can customize them to meet the specific needs of your company.

With these facts in mind, how can you get the most out of your hydraulic motor? Learn more about how they work.

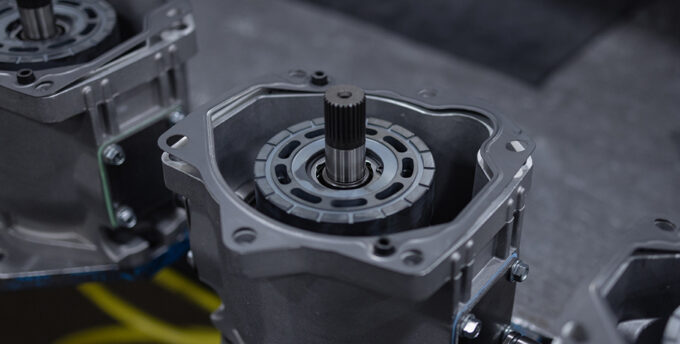

How Do Hydraulic Gear Motors Work?

If you have a hydraulic gear motor, it will take advantage of gears that will increase or reduce the shaft output speed depending on your application. In general, the pressure of a gear motor is relatively low, falling between 100 and 150 bar. Even though this is a strong motor, if you have applications that require a lower speed, the motor can also be relatively noisy.

This is a lightweight, small unit that can generate enough pressure to handle numerous applications. They are known for their low cost, wide temperature range, wide speed range, and straightforward design. They are also very easy to take care of.

How Do Hydraulic Vane Motors Work?

Another option you may be interested in is a hydraulic vane motor. This type of motor is commonly used in mobile and industrial applications. They are ubiquitous throughout injection molding and agricultural machinery. They tend to leak significantly less than a gear motor, so they are much better with applications that require lower speeds.

These types of motors have a relatively low noise level, a significant amount of torque, and a straightforward design. They are very easy to service, and they work well if they are installed vertically. You can customize the volume displacement and pressure to meet your specific needs. They will also generate a significant amount of torque, helping you complete projects and run daily operations.

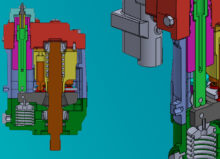

The Different Types of Radial Piston Motors

Finally, you might also be interested in a radial piston motor. This is a very efficient motor that has a long life. They can also generate a significant amount of torque even if the shaft speed is relatively low. Furthermore, a gearbox is not always necessary to take advantage of a piston motor.

Radial piston motors are commonly used in excavators, drilling equipment, concrete mixers, and plastic injection molding machines. There are also two separate types of radial piston motors.

The first is called a crankshaft radial piston motor. This has a single cam and piston that pushes inward. It has a high starting torque and can run at slow, creep speeds.

The second is called a multilobe cam ring design. There is a cam ring with multiple lobes and piston rollers that push outward against the ring. It has a smooth output with a very high starting torque.

There are other types of radial piston motors as well. These include compact radial piston motors, fixed displacement radial piston motors, and dual displacement motors.

Panagon Systems for Your Hydraulic Motor Replacement Parts

If you are looking for help repairing your hydraulic motor system, then you need to rely on the team from Panagon Systems. We provide you with access to an unparalleled variety of parts. We can also work with you closely, helping you find the right motor to meet your needs. Our professionals are always ready to help you, so contact us today to learn more about our hydraulic motor replacement parts! It would be our pleasure to assist you and your business.