How Do Hydraulics Systems Work?

Are you curious about hydraulic pump systems, what they are, and how they’re used? In this article, we explain the basics of hydraulic systems, the many types of systems, how they work, and best practices for taking care of them.

What Is a Hydraulics System?

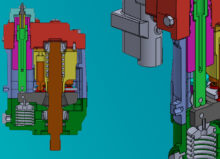

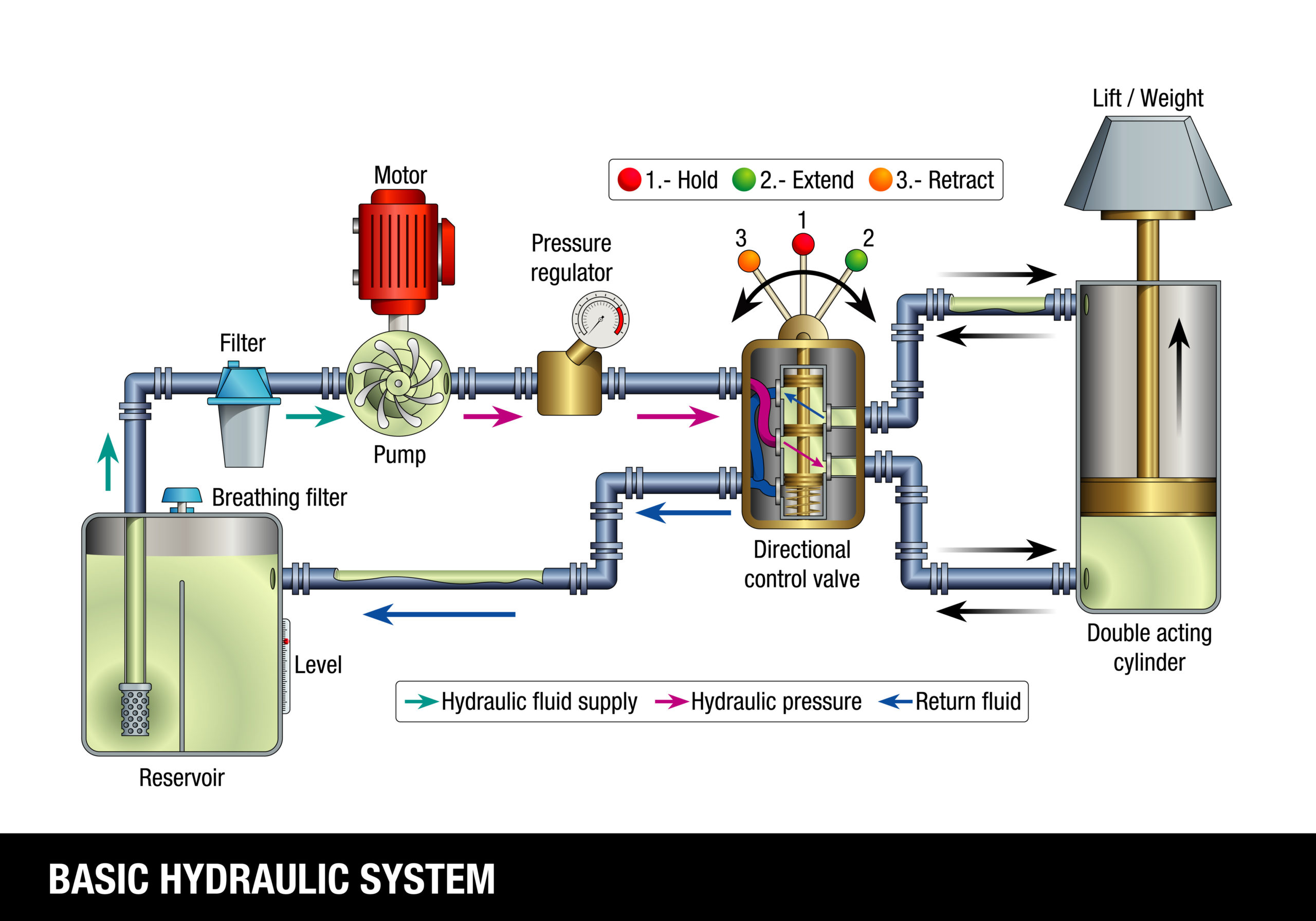

A hydraulics system uses compressed fluid to transfer an applied force between two different points. There are quite a few basic parts that make up a hydraulics system, including a cylinder, filter, motor, fluid, valves, hose, pump, and reservoir.

- Cylinder: A hydraulic cylinder applies unidirectional force and is considered the system’s muscle.

- Filter: The purpose of a filter is to remove impurities from the fluid.

- Hydraulic Fluid: This is extremely crucial to the system’s entire operation; it helps cool the system, drives away contaminants, and transfers energy.

- Motor/Prime Mover: The motor uses pressure from the fluid and converts it into mechanical energy.

- Valves: The valves are another critical component of a hydraulics system. They direct where the hydraulic fluid flows.

- Hose: As previously mentioned, valves direct the flow of fluid in the system. Valves are a component of the hydraulic hose.

- Pump: Once the motor converts fluid pressure into mechanical energy, the pump converts the mechanical energy into hydraulic energy.

- Reservoir: Think of a reservoir as the hydraulic system’s septic tank. The reservoir stores the fluid and separates any solid contaminants from the fluid. It is also used for heat transfer.

How Does a Hydraulics System Work?

- The hydraulic fluid first gets pumped out of the reservoir into various pipes.

- It passes into an actuator after going through some control valves.

- The fluid’s pressure on a piston exerts a certain load force, generating rotational motion or linear motion on a specific load.

- Liquid on the piston’s opposite side becomes pressurized, travels through the pipes, and returns to the pump or the reservoir. This ensures that you don’t lose any fluid, and this sealed circuit will lubricate itself, too.

Additionally, if you connect multiple circuits, each circuit’s load force can provide power to the next one. You can use this force multiplication to lift or push heavy loads.

Types of Hydraulics System

The two main types of hydraulic systems are open-loop and closed-loop. If you use an open-loop system, there is no pressure, but the fluid flows when the actuating mechanism is idle. A closed-loop system creates pressure for the fluids when the pump is active.

Another difference is that a closed-loop hydraulic system utilizes a feed pump or a charger pump, while a directional control valve is used in an open-loop system.

Types of Hydraulic Pumps

There are two types of pumps that can appear in a hydraulics system: fixed displacement and variable displacement.

Fixed

A fixed displacement pump moves a certain amount of fluid using the motor’s every stroke. If you need a hydraulic pump for a single function, a fixed displacement pump is the best choice. Also, fixed displacement pumps are easy to maintain and will give you high flow rates even with a fairly low amount of pressure.

Variable

A variable displacement pump is better if you have to use it for many tasks. The designs of variable displacement pumps are a bit more complex than fixed pumps. Additionally, it is worth noting that it costs more to maintain and produce a variable displacement pump, too.

Examples & Applications of Hydraulics Systems

Hydraulics systems are used in many industries and have many applications. The most common applications include:

- Hydraulic Press

- Hydraulic Workholding System

- Hydraulic Excavator

- Dishwashers

- Gas Pumps

- Airplanes

- Office Chairs

Additionally, the construction industry relies on hydraulics systems for concrete pumping, brick molding, and more, while farmers may need hydraulics systems for their equipment. Another industry that relies on hydraulics systems is the automotive industry; vehicles use hydraulic systems for braking, steering, cooling, and more.

When Are Hydraulics Systems Needed?

Hydraulics systems typically put out more force than other systems, like mechanical, electrical, and pneumatic. A hydraulics system might be the right choice if higher power and better safety are needed.

Do Hydraulics Systems Need Maintenance?

Yes. Best maintenance practices for hydraulic systems include:

- Regularly checking fluid levels and filters

- Replacing filters when necessary

- Inspecting the system for fissures, cracks, and wear.

- Inspecting the pump’s fittings, clamps, shaft seals, and intake lines.

- Using an alarm to monitor fluid temperature

- Ensuring you’re using the right hydraulic oil in your system (recommend viscosity, etc.)

Routine maintenance will ultimately help you prevent expensive repairs down the road. Additionally, it’s best to utilize a heat exchanger appropriate for the hydraulics system. You should get rid of anything causing aeration or vapor cavities by using a well-designed system and suitable return line filters.

Learn More From Panagon Systems

Founded over 25 years ago, Panagon Systems is an industry-leading manufacturer of aftermarket hydraulic piston pumps and motors. If you want to learn more about hydraulic pumps and systems, please browse our blog for more resources, or contact us today if you’d like to hear more about our capabilities.