The Three Types of Hydraulic Motors

The primary function of a hydraulic motor is to convert hydraulic energy into mechanical power. There are three major types of hydraulic motors: gear motors, piston motors, and vane motors.

Keep reading to learn more about each type of motor, including their benefits and common applications.

How Are the Types of Hydraulic Motors Classified?

High-speed, low-torque (aka HSLT) and low-speed, high-torque (LSHT) are the two main classifications for hydraulic motors. LSHT motors typically provides significant power from a relatively small drive envelope. This gives them a wide array of benefits, including low vibration and noise.

Next, let’s look at how the different types of hydraulic motors are rated.

Rating Hydraulic Motors

Hydraulic motors are rated by torque and displacement.

Displacement refers to the volume of fluid that the motor requires in order to rotate its shaft once. In any case, the ratings for the displacement of hydraulic motors are either cubic centimeters per revolution or cubic inches per revolution. In contrast, the common measurements for the torque of a hydraulic motor are Newton-meters and inch-pounds.

You should also know that the Society of Automotive Engineers and the International Organization for Standardization maintain their own separate standards for hydraulic motors, too.

Now that you know more about the ratings and classifications of hydraulic motors, let’s discuss the three main types, starting with gear motors.

Gear Motors

The first type of hydraulic motor is the gear motor. There are two parts that make up a hydraulic gear motor. These parts are the idler gear and the driven gear. The output shaft is attached to the driven gear using a key. You port high-pressure oil into one of the gear’s sides, and then it flows between the wall housing and the gear tips into the outlet port. After that, the gears mesh, which prevents the oil in the outlet side from returning to the inlet side.

Low initial cost and greater tolerance to contamination are a few benefits of gear motors. Additionally, gear motors are generally quite durable, too. Fans, screw conveyors, and dispersion plates are a few common applications of hydraulic gear motors.

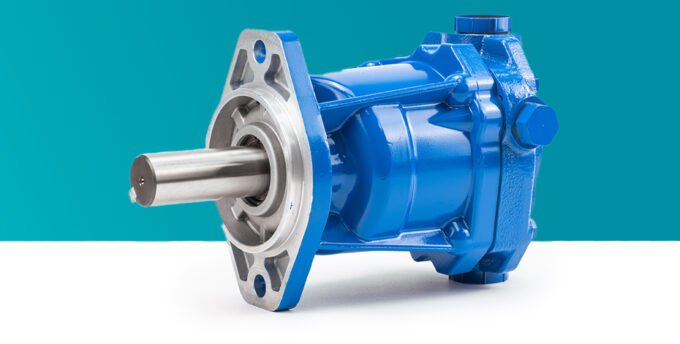

Vane Motors

Next, there are vane motors. This type of hydraulic motor has a housing that includes an eccentric bore. In this bore, a rotor runs and it has vanes that slide in and out of it. The hydraulic fluid goes into the motor and this fluid goes into a rectangular vane. The main output shaft and the center rotor are connected. The application of the fluid to the vane makes the output shaft rotate.

Simple design and low noise levels are two benefits of vane motors. Most vane motors also generate high torque at low speeds. Some common applications of vane motors are agricultural machinery and screw-drive molding.

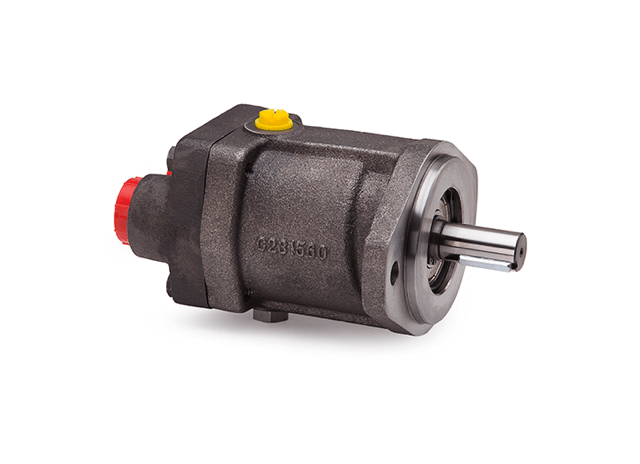

Piston Motors

The last type of motor is a piston motor. Within this type, there are two categories: radial and axial.

Radial-Piston

Radial-piston motors are classified as LSHT motors. The pistons in these motors are perpendicular to the output shaft. Higher output torques are one benefit of radial-piston motors. Another benefit is that these motors will give you a smoother output speed when operating at low speeds.

Ground drilling equipment is one common application of radial-piston motors. Winches and cranes are two more common applications of these motors. These motors are also used in caterpillar drives of dragline excavators.

Axial-Piston Motors

The design of an axial-piston motor consists of pistons located in a circular array inside of a cylinder block. Benefits of axial-piston motors include better speed variability, greater speeds, and higher efficiencies. Some common applications of these motors are to drive winches, construction equipment, and ship cranes.

Choosing the Right Hydraulic Motor

The first step in selecting the correct type of hydraulic motor is knowing the application for the motor. Knowing this means that you know the performance needs, including temperature, speed, pressure, and operating torque.

You should also consider if you need a motor that is easy to install, or if your industry has set any specification requirements. It is good to examine the potential of contamination as well.

If you work with a professional hydraulic supplier and manufacturer, this will help you improve your decision-making.

Have Questions? Contact Panagon Systems Today!

Panagon Systems has been a leading aftermarket manufacturer and supplier of hydraulic motors for over 25 years. Based in Macomb, MI, we serve clients across the U.S. If you’re not sure which type of hydraulic motor is best for your application, contact us today to speak with one of our experts.