Should You Repair or Replace Your Hydraulic Pump?

Hydraulic pumps are critical components within hydraulics systems that generate liquid flow by converting mechanical energy to hydraulic or fluid energy. Scheduled maintenance and regularly looking for signs of failure help to prevent premature failure and costly repairs.

In this blog post, we’ll cover the common signs of hydraulic pump failure and considerations when choosing between repairs and a complete replacement.

Signs of Failure

- Internal Leaks

- External Leaks

- Fluid Contamination

- Loud Noises From the Pump

- Reduced System Performance

The most noticeable signs of potential failure are interior or exterior leaks. These can often be caused by a torn, pinched, or ripped O-ring, seal, spacer, or snap ring. However, they can also be caused by internal sub-components that may have been cracked or fractured during operation.

Constantly replacing O-rings, seals, and spacers could point to an offset, slight bent, or misalignment in the drive shaft. Other signs of failure include fluid contamination and the hydraulic pump skipping or making loud sounds. Lastly, a malfunctioning pump can reduce the overall performance of your hydraulics system. If you’ve noticed a decline in performance, you may need to repair or replace your pump.

Troubleshooting Common Issues

You can proactively avoid a pump or total system failure before it worsens with routine visual and auditory checks. Here are some ways you can troubleshoot common pump issues:

Internal & External Leaks

Both are fairly easy to spot. In the worst cases, you’ll see a drop in oil pressure or excessive leaking. Check the oil level to ensure no air is seeping into the pump. You might need to check the condition of the O-rings, gaskets, and seals and replace them to resolve these leaks. Again, frequently changing these could point to an internal fracture or break of one or more internal subcomponents.

Low or No Pressure

If you notice your hydraulics system’s pressure has dropped or there’s no pressure at all, immediately stop the system. It could indicate low oil levels, internal mechanical issues, a clogged intake valve, or even internal corrosion impacting the movement of the piston rod/drive shaft.

Loud Rattling Noises

A clunking or rattling sound could indicate cavitation, which occurs when gas bubbles form within the pump. These bubbles appear because the pump can’t get the right amount of oil to operate efficiently. The bubbles accumulate within the hydraulic pump until they pop and release air into the system. In return, the system will often see a noticeable decline in pressure.

To fix cavitation issues, you may need to increase the fluid level in the reservoir, install suction lines, or reduce the flow rate.

Over-Pressurization

Exceeding the pump manufacturer’s specific pressure levels and ratings can cause severe damage to the pump and its parts and subcomponents. A malfunctioning, damaged, or cracked check valve will redirect oil back into the pump, causing damage to its internal components, hoses, and seals. Monitoring the pressure levels and never exceeding the OEM-specified pressure rating ensures that over-pressurization doesn’t damage the pump and the entire hydraulic system.

Oil/Fluid Contamination

Oil with an off-white or milky appearance indicates fluid or water contamination. Immediately shut off the hydraulic system as the contamination can cause damage to the pump’s internal components, including the valve plate, driveshaft/piston, bearings, and cylinder block. Contaminants and particulate matter can scratch or erode the pump’s internal parts, slowing the pump down or creating excessive friction between component mating surfaces.

Once fluid becomes contaminated, it can easily infiltrate the system and may be difficult to resolve. If there is contamination, you’ll need to flush the entire system and add new fluid. Installing filters on your pump is recommended to reduce future risks of contamination.

When Repairs Are Necessary

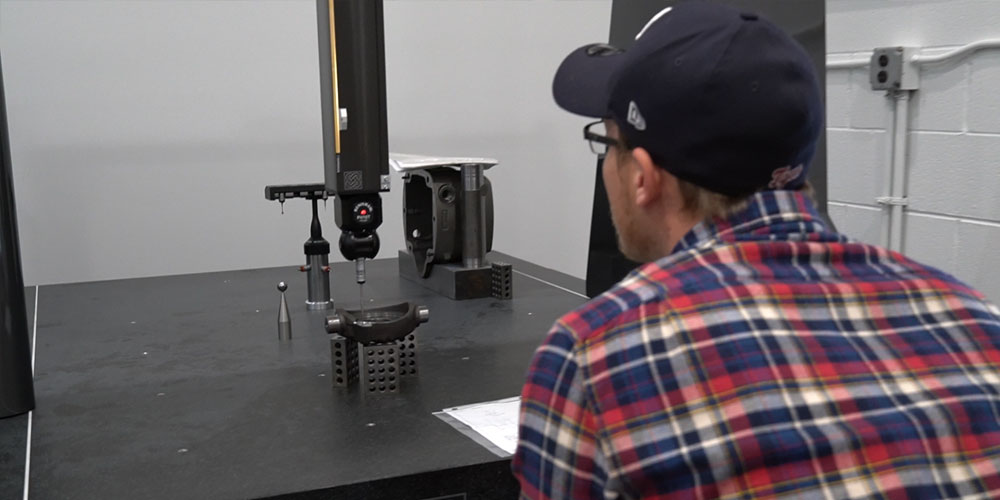

Hydraulic pumps can be repaired in most scenarios. In most cases, a hydraulic pump repair involves disassembling the pump, identifying the problem, replacing defective parts with new ones, and cycling the pump before putting it back to use.

Repairing a pump is faster than getting an OEM replacement. The question you must ask is whether the cost of the repair is higher than or half the cost of a new pump. Given that most pump issues can be repaired, choosing the least expensive option is best.

Cost of Repairing a Hydraulic Pump

Unfortunately, there are no hard and fast rules concerning the costs of a hydraulic pump repair. Each situation and reason for failure is different. The cost of a hydraulic pump repair depends upon the severity of the problem, how long it takes to disassemble the pump, and how many parts need to be cleaned or replaced.

For reference, a new cylinder block costs anywhere from $100 to $700, gaskets and O-rings can go for $5 to $10, and individual bearings can cost $8. From there, it’s a question of how many internal components need replacing, plus labor costs.

When Replacements Are Necessary

Hydraulic pumps are designed for long in-field service lives. A hydraulic pump replacement is often only needed when the pump is approaching its expected lifespan. Another reason for replacing a pump is to protect the entire hydraulic system. If the pump continuously damages that system, a replacement is needed.

Another situation where a replacement is preferred is when the replacement cost is less than the repair cost. This is often the case when too many components need repair and refurbishing, and the costs of the repair exceed the replacement costs.

Cost of Replacing a Hydraulic Pump

The cost of a replacement typically comes down to the type of pump being replaced, its function, and the hydraulic system it operates in. While these conditions vary, you can still plan to spend between $1,500 to $4,000 for a replacement pump, with OEM replacements being more expensive and with longer lead times.

Direct OEM Versus REMAN Replacements

If your pump is failing or has already failed, waiting for a direct OEM replacement can be time-consuming. Purchasing a remanufactured or OEM-equivalent pump can help you reduce downtime. Plus, most remanufactured pumps undergo extensive testing to ensure quality, and they are far less expensive than OEM replacements.

When purchasing remanufactured pumps, ensure your chosen supplier offers warranties and thoroughly tests the pumps to ensure they meet or exceed OEM specifications.

Where to Purchase OEM-Quality Hydraulic Piston Pumps

Panagon Systems is a trusted manufacturer of aftermarket Vickers/Eaton and Rexroth A10-V-30/-31 hydraulic piston pumps and motors in the United States. All pumps we manufacture are thoroughly tested to ensure they meet or exceed their original OEM specifications and are backed by an 18-month warranty.

We also repair and rebuild all types of Rexroth and Vickers/Eaton parts and provide high-quality replacement components, including O-rings, cylinder blocks, seal kits, and compensators.

Please contact us today to learn more about our capabilities or to request a quote.