How Does a Two-Stage Hydraulic Pump Work?

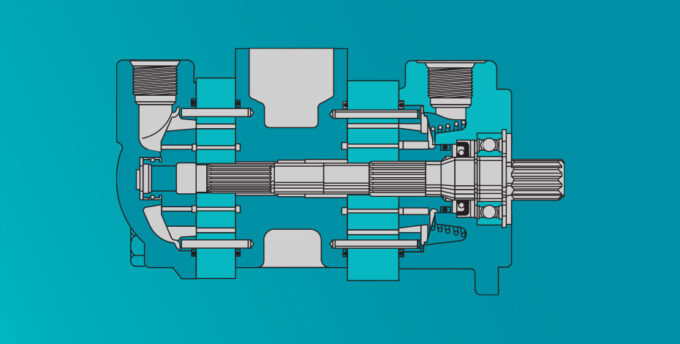

A two-stage hydraulic pump uses two pumps to generate high and low liquid flow rates and high and low pressure without requiring higher power consumption. A low-pressure, high-rate inlet valve and a high-pressure, low-flow rate outlet valve allow the pump to generate higher oil pressure at a lower or higher flow.

Common Uses

Two-stage pumps are commonly used in log splitters and compactors. In fact, a two-stage pump is sometimes called a log splitter pump because the two-stage pump generates sufficient pressure to split a log while generating a consistent cycle rate by controlling fluid flow.

Compactors also use two-stage hydraulic pump systems. A trash compactor, trench compactor, or construction equipment like vibrating plates, rammers, and tandem rollers reduce material thicknesses through compaction. The pump’s high-pressure flow initiates the compacting rod, while the pump’s low-pressure flow retracts and feeds the high-pressure chamber.

One-Stage Versus Two-Stage Pumps

A single-stage pump includes a motor that rotates a single impeller to generate fluid flow, and it’s generally ideal for low-pressure applications requiring a consistently high flow rate. Comparatively, a two-stage pump has a motor driving two impellers that manage the flow rate and pressure. It is ideally suited for situations where maintaining a high head pressure is necessary.

When to Use a Two-Stage Hydraulic Pump Over a Piston Pump

With piston pumps, there are two chambers consisting of an inlet and outlet valve or orifice. The pistons reciprocating motion drives liquid or fluid into and out of a chamber. Pump adjustments, like torque or horsepower limiters, allow piston pumps to emit a maximum flow rate regardless of pressure level. These are more expensive than two-stage or gear-based pumps and are more suited for high-speed and high-pressure applications.

Piston pumps are far more expensive than two-stage pumps, and these costs are only exacerbated if the piston pump encounters a failure and requires part replacements or refurbishing. Two-stage pumps don’t require as much fuel and power as piston pumps, making them ideal for applications like log splitting, where the cycle speed of the pump can heavily influence work output.

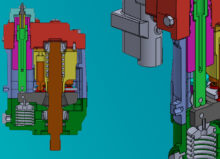

How to Turn Off or Alternate a Two-Stage Pump

Alternating the two-stage hydraulic pump between units is coordinated by the check and unloader valves.

1. Fluid is drawn from a reservoir into a high volume, large-gear unit, elevating the gear housing’s pressure level.

2. Once the first-stage pressure meets a certain pressure threshold, a combiner check valve will open and feed into the second-stage, small-gear unit – joining flows at relatively low pressure.

3. A load sensing pin will trigger the unloading valve to open and the check valve to close. The flow will be directed exclusively to the discharge port.

4. A small amount of fluid may feedback to a load sensing pin to measure the pressure at the outlet and signal lower flow rate in the first unit, lowering the pressure and providing the conditions for a cycle to repeat.

Learn More From Panagon Systems

Panagon Systems is an industry-leading manufacturer of aftermarket hydraulic piston pumps, motors, and replacement parts. Contact us today if you need help selecting the right pump type for your unique application.