Types of Hydraulic Pumps

Hydraulics use mechanical energy to force liquid into two different points and are used in many commercial and industrial applications, from cranes and forklifts to automotive lifts.

Hydraulic pumps are a significant component of a hydraulics system, as it is responsible for converting mechanical energy into hydraulic energy. There are many different types of hydraulic pumps used within these systems. In this article, we’ll take you through what these different pumps are and how they work.

Piston Pumps

A piston pump is a positive displacement device. In these pumps, there is a high-pressure seal that combines with a driving piston to move liquids and gasses. One of the main advantages of piston pumps is that they are incredibly versatile and can operate well under various pressure settings. Piston pumps are also effective at dealing with solid particles and viscous media.

In most piston pumps, there is a piston cup that moves using an oscillation mechanism. When the pump moves downward, it causes pressure differentials. When the pressure changes, the pump chambers fill up. When the piston goes up again, it forces fluid out of the section.

Piston pumps are commonly used when constant, high pressure is required, like in delivery systems and water irrigation.

The two primary types of piston pumps are axial and radial.

Axial Piston Pumps

An axial piston hydraulic pump is a type of positive displacement pump. They have cylinders assembled around a central axis (cylinder block). Within each cylinder are pistons attached to a swashplate or wobble plate. These swashplates connect to the rotating shaft, which moves the pistons and pulls them in and out of the cylinders.

Axial piston pumps can have both fixed and variable displacement. Variable displacement provides more control over speed. In variable pumps, the swashplate is used to set the depth of the pistons, creating a length variation that affects the discharge volume. Read this article to learn more about the differences between fixed and variable displacement pumps.

Radial Piston Pumps

As its name suggests, in a radial piston pump, the pistons are arranged along the radius of the cylindrical block, which includes the pintle and rotor. The rotor powers the pistons through the cylinders and forces hydraulic fluid in and out of the cylinder.

Both axial and radial piston pumps are used for high-operating pressures as they can withstand much higher pressures than hydraulic pump types. They are often used in ice and snow control applications, as well as on truck-mounted cranes.

Vane Pumps

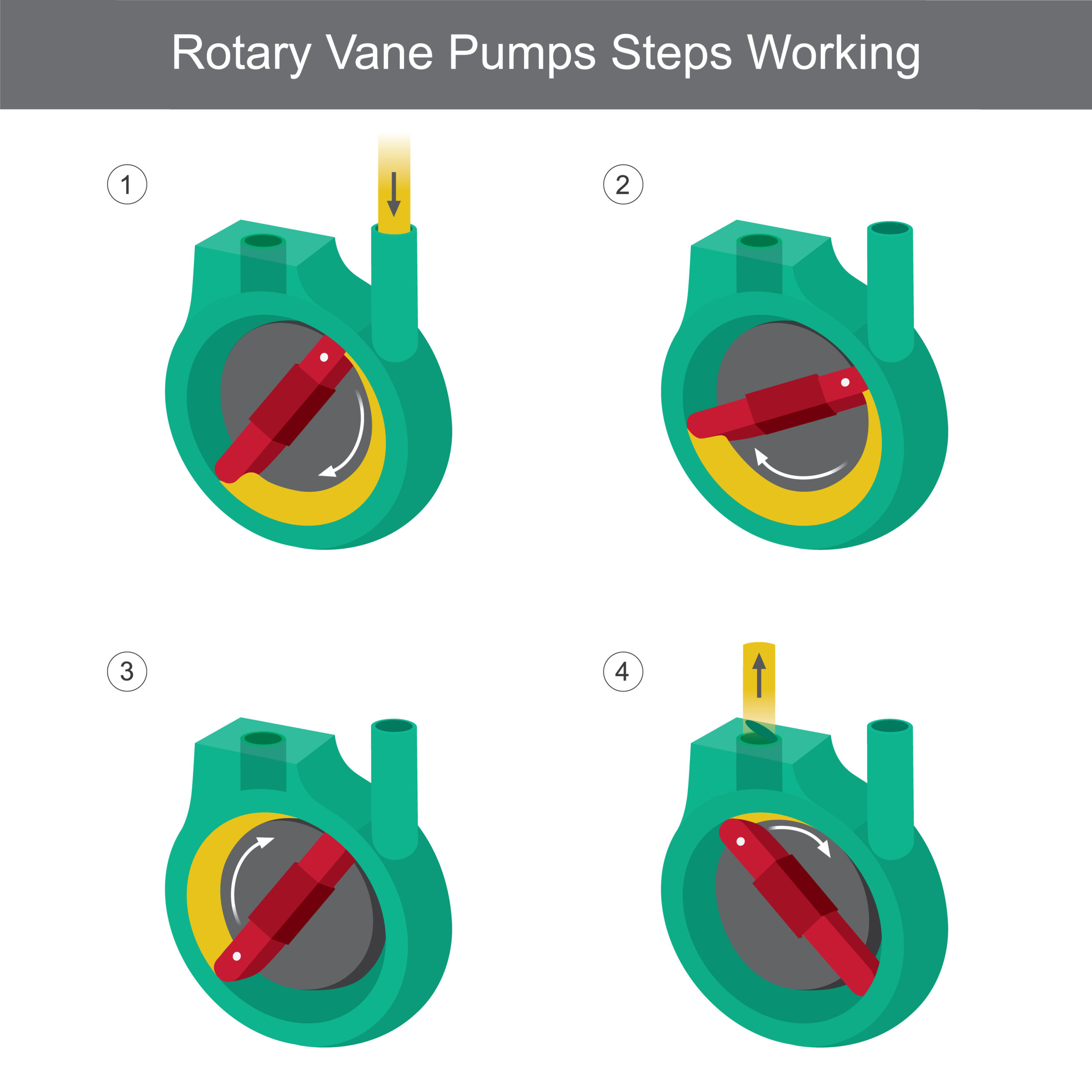

A vane pump is a positive displacement pump designed to provide the same amount of flow even as the pressure changes. This pump type usually has a maximum rotational force of 900 rotations per minute.

A rotary vane pump uses rigid vanes rather than the rotor hubs. These vanes are placed around an eccentric rotor device, which moves around the inside wall of the housing container. This movement forces the hydraulic fluid through the discharge port and, in some applications, can be adjusted to align with the rotational axis of the motor.

Furthermore, the pump is combined with a relief valve. The valve is designed to prevent the pump from building up so much pressure that it may damage itself. If there is excess pressure, it vents through the relief valve, protecting the system.

One of the main advantages of a rotary vane pump is that it is reversible. So, it is an outstanding choice for applications where stripping and unloading individual tanks might be necessary. The size of the rotor, the vanes, and the chambers can be customized.

Vane pumps are often used in utility vehicles but have lost popularity over the years in favor of gear pumps. However, they used to be very common in aerial buckets and ladders along with other mobile, truck-mounted hydraulic applications.

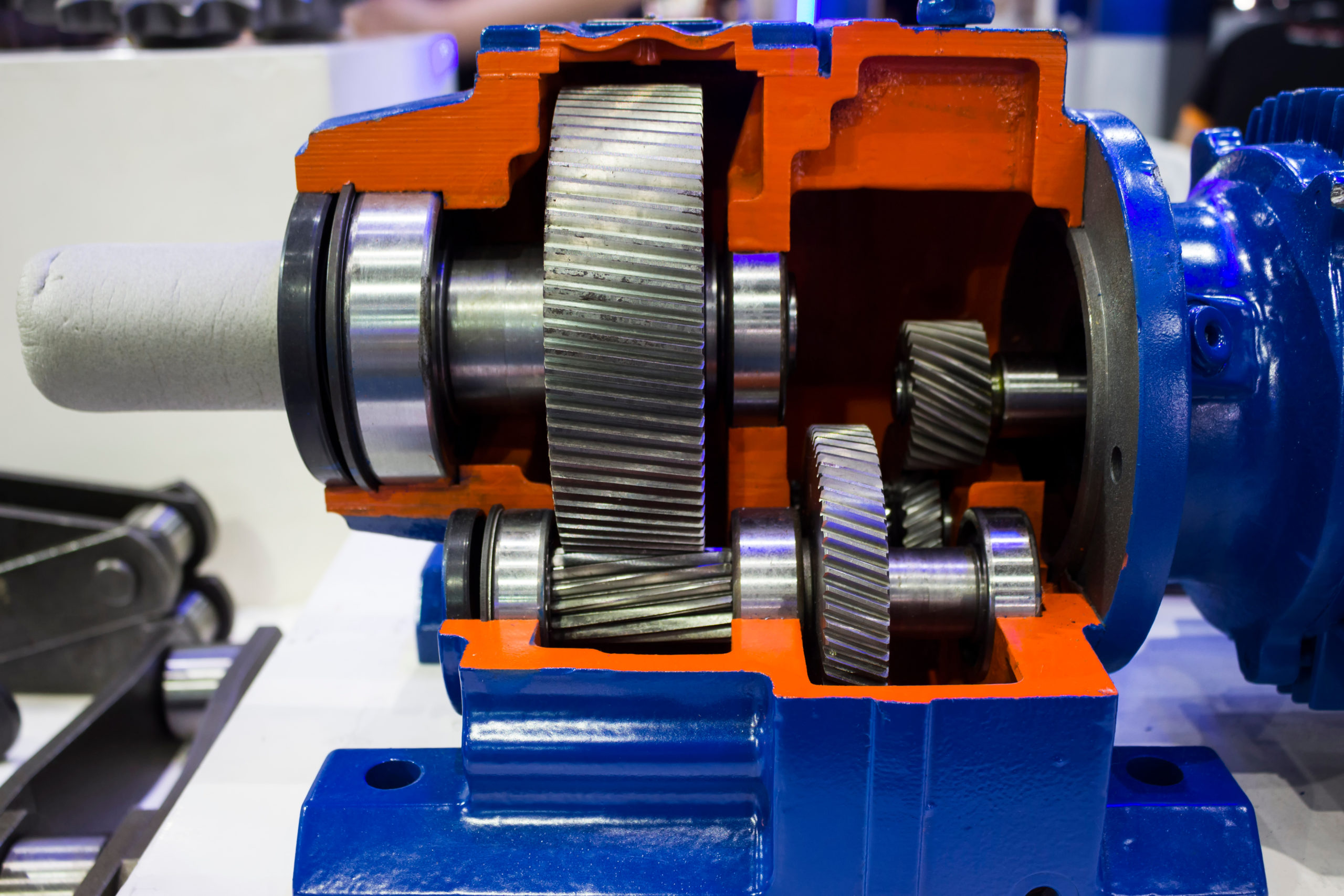

Gear Pumps

Gear pumps have become the most common hydraulic pump type used in industrial applications today. The gear pump has fewer moving parts than piston or vane pumps, which makes it easy to service and relatively inexpensive compared to other hydraulic pumps. They are also less likely to be contaminated during use.

There are two major types of gear pumps: external and internal.

External

An external gear pump uses two gears on the outside of individual shafts to aid movement and push thin and thick fluids through the gears. These external pumps are commonly used in fixed-displacement applications and high-pressure environments.

Internal

Internal gear pumps place gears on the insides of the shafts rather than on the outside, as found in external gear pumps. This gear placement makes internal pumps self-priming and non-pulsing and can even be run without liquid for short periods—although they can’t be left dry for too long.

Internal gear pumps are also bi-rotational, meaning that one can be utilized to both unload and load devices. And, with only two moving parts, they are considered one of the most reliable hydraulic pump types.

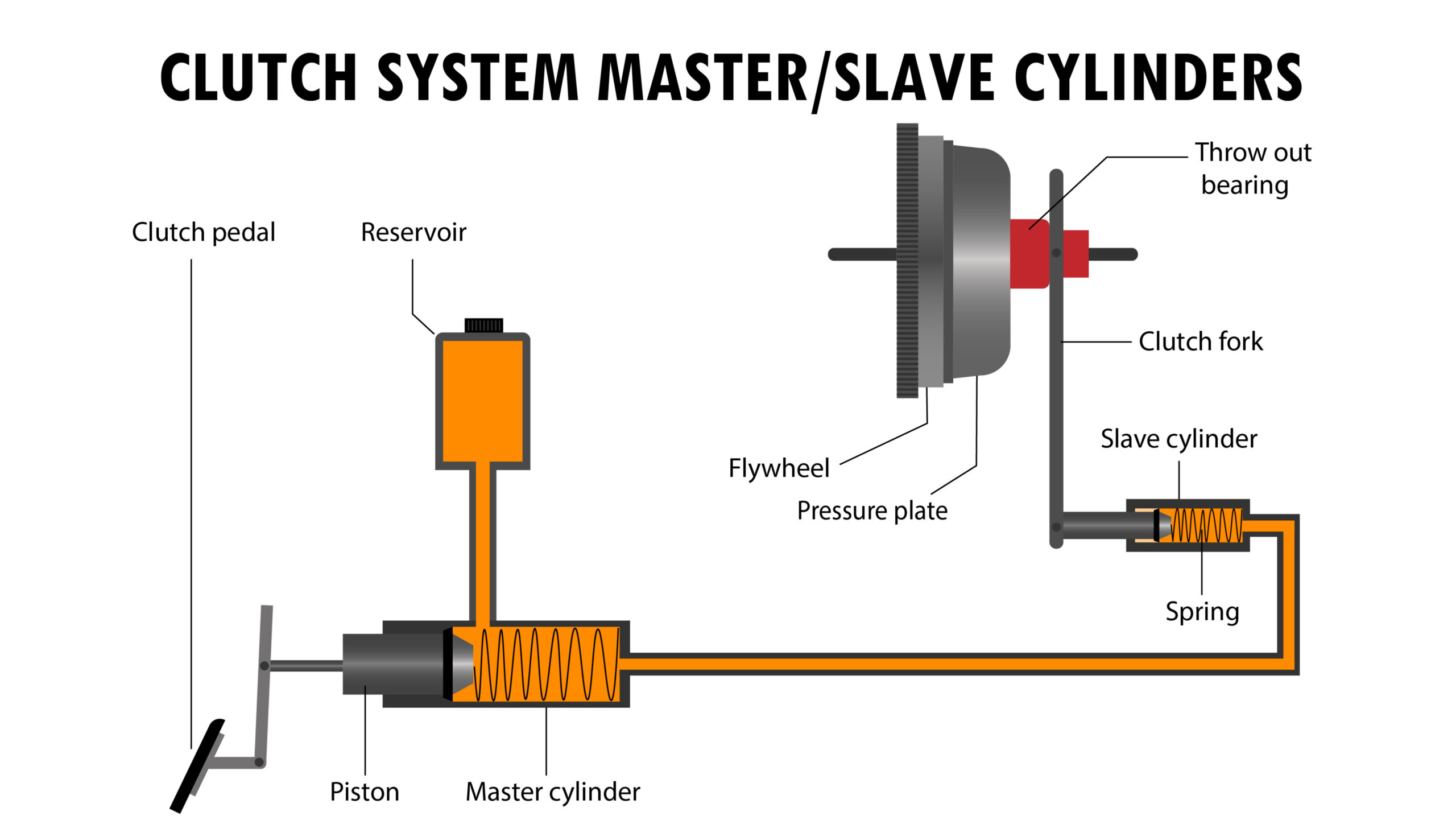

Clutch Pumps

A clutch pump uses a belt from a crankshaft pulley to drive itself. When a clutch pedal is engaged, the flywheel moves with a pressure plate to disengage the clutch disc and prevent the driveshaft from turning. When the clutch pedal is released, the plate re-engages. The clutch pump helps move fluid from the pedal to the clutch mechanism.

This pump type is commonly used in bucket trucks, wreckers, and other types of heavy equipment. A clutch pump is usually mounted to the engine compartment of the truck. There is a mounting kit that is required to secure it in place. If you use this type of pump, you need to ensure there is enough space underneath the hood.

Which Type of Hydraulic Pump Has the Highest Volumetric Efficiency?

The rotary vane pump offers the highest volumetric efficiency.

Volumetric efficiency is the amount of output the pump actually produces as a percentage of its theoretical production. The higher the percentage, the more efficient the pump.

Among the factors affecting volumetric efficiency are leakage and fluid compressibility (the ability for volume to be reduced under pressure). These issues can cause the pump to lose efficiency and waste energy as that energy converts to heat.

Choosing the Right Pump

The type of pump you need will depend on your application.

Evaluate your application to determine the required flow rate, pressure, and fluid type. Next, consider your operating conditions and environment. What temperature ranges will the pump operate in? Is your environment rugged or extreme? How much space do you have for a pump?

Lastly, look at your budget and how much you are willing to spend on a pump.

Piston pumps are known for being highly efficient and excellent choices for applications with high pressure and flow rates, but they are more complicated and tend to be more expensive than other types of pumps. Comparatively, vane pumps are great for lower-pressure applications and usually operate with less noise and vibration, but aren’t as efficient as piston pumps.

Gear pumps are simple, cost-effective, and relatively easy to maintain, but they don’t offer variable displacement capabilities and aren’t suited for high-pressure applications. Lastly, clutch pumps offer more control and are easier to install, but are only ideal for applications where intermittent pump operation is beneficial.

Get Help Selecting the Right Pump

Panagon Systems is proud to be the largest aftermarket hydraulic manufacturer in the United States. We specialize in manufacturing obsolete and discontinued pumps and pump components from brands like Vickers/Eaton and Rexroth. Our experts can help you find the best replacement pump for your application—we can even customize your pump based on your unique needs!

Contact us today to learn more about our manufacturing and design capabilities, or visit our blog for more hydraulic pump resources.